09

Sep

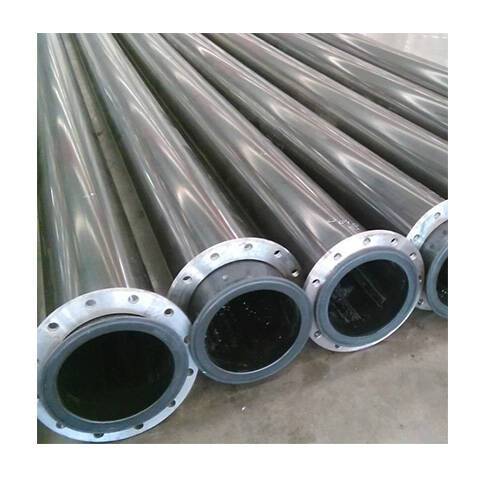

6 Reasons Why HDPE Water Pipes Burst

1️⃣ External Pressure: Excessive external pressure on the pipes, such as heavy traffic loads, ground movement, or improper backfilling during installation, can lead to pipe bursting.

2️⃣ Temperature Changes: Extreme temperature variations can cause HDPE pipes to expand or contract, leading to stress and potential bursting. Freezing temperatures are of particular concern as the frozen water inside the pipes can expand and cause them to rupture.

3️⃣ Improper Installation: Poor installation practices, such as inadequate fusion techniques, incorrect alignment, or improper jointing, can weaken the integrity of the HDPE pipes, making them more susceptible to bursting under pressure.

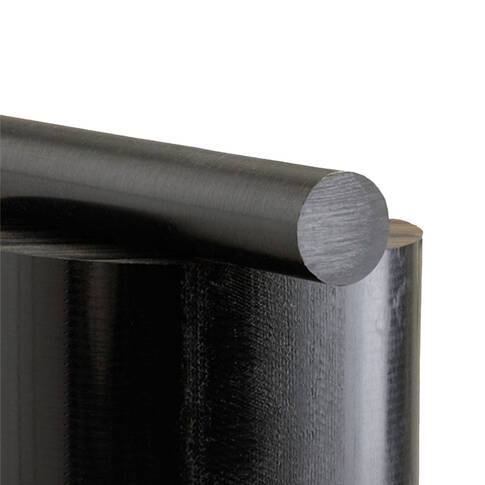

4️⃣ Insufficient Wall Thickness: If the HDPE pipes are manufactured with insufficient wall thickness for the intended application or if thinner sections develop due to wear, degradation, or damage, they can be more prone to bursting.

5️⃣ Chemical Exposure: Exposure to harsh chemicals or corrosive substances can degrade the HDPE material over time, reducing its strength and making it more prone to bursting.

6️⃣ Manufacturing Defects: Issues during the manufacturing process, such as improper resin blending, inadequate quality control, or material impurities, can weaken the HDPE pipes and contribute to bursting.

🔧 Regular inspections, proper installation techniques, avoiding excessive pressures, using appropriate wall thickness, and protecting pipes from extreme temperature variations and chemical exposure can help prevent bursting in HDPE water supply pipes.