18

Aug

Learn More About HDPE Coil Pipe From Shallow To Deep

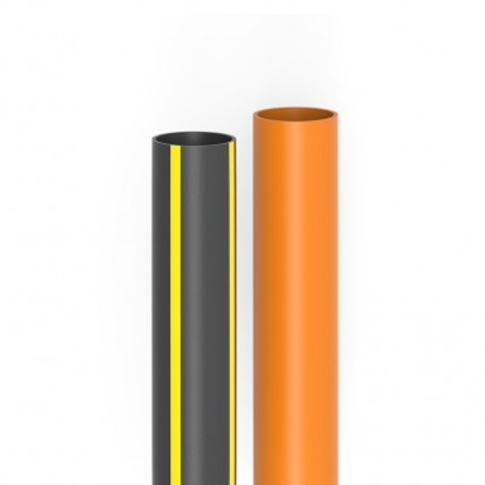

HDPE coil pipes, also known as High-Density Polyethylene coil pipes, known for its high strength, durability, and flexibility. These pipes are manufactured in a coiled form, which offers ease of transportation, storage, and installation. HDPE coil pipes are commonly available in various diameters, wall thicknesses, and coil lengths, making them suitable(DN20mm-110mm, 100m or 200m a roll) for a wide range of applications.

One of the main characteristics of HDPE coil pipes is their exceptional resistance to corrosion, chemicals, and UV radiation. This makes them an ideal choice for water supply, gas system. Unlike other materials like PVC pipes, HDPE coil pipes do not conduct electricity, ensuring the safety of the users and preventing potential accidents. Additionally, these pipes have a smooth inner surface that minimizes friction and ensures high flow rates, making them highly efficient.

Another essential characteristic of HDPE coil pipes is their flexibility. The coiled design allows the pipes to bend and adapt to different terrain types, minimizing the need for additional fittings and reducing the overall installation cost. This flexibility also makes HDPE coil pipes suitable for underground applications, such as agricultural irrigation, sewerage systems, and telecommunications.

HDPE coil pipes Lightweight, easy to transport and install. Contractors and workers can handle and maneuver these pipes effortlessly, reducing the labor required for installation projects. Additionally, the lightweight feature enables cost-effective transportation, as larger lengths of pipe can be loaded onto trucks, reducing the number of trips needed.

HDPE coil pipes find applications in various sectors. In agriculture, these pipes are widely used for irrigation purposes, as they can be easily laid out and transported across large fields. Their resistance to chemicals also makes them suitable for the transportation of fertilizers and pesticides.

The construction industry relies on HDPE coil pipes for underground cable and wire protection. The flexibility and durability of these pipes ensure long-lasting protection, reducing maintenance needs. Furthermore, these pipes are commonly used in plumbing systems due to their corrosion resistance and high flow rates.

In the telecommunication sector, HDPE coil pipes are employed for the installation of fiber optic cables. Their smooth inner surface prevents damage to the cables and ensures efficient transmission of data over long distances.

HDPE coil pipes are also utilized for transporting industrial chemicals, sewage, and slurry in various industrial applications. Their chemical resistance, flexibility, and durability make them an excellent choice for such demanding environments.