24

Jul

Precautions Of HDPE Pipe Butt Fusion Connected

526

High-Density Polyethylene (HDPE) Pipes is a versatile material widely used in various industries for its excellent strength, durability, and resistance to chemicals. When it comes to joining HDPE pipes, have 4 Method For HDPE Pipe Most Commonly Joining,the butt fusion process is commonly employed. HDPE Pipe Butt Fusion Joining Procedure has 5 steps: Prepare, Assemble, Heat and Fusion, Joining and Connect, Cooling and Inspection

When connecting HDPE pipes with a butt fusion welding machine, there are some precautions about the use of various parts of the welding machine, please read below

Precautions Of HDPE Pipe Butt Fusion Connected

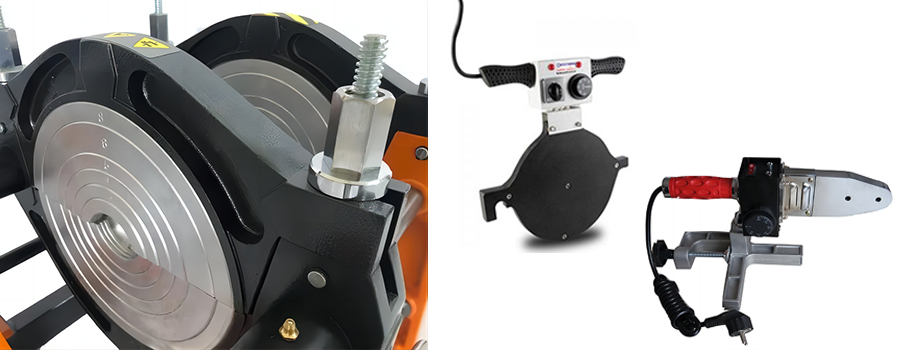

1. Heating plate

The maximum temperature of the heating plate can reach 250°C, so the following items must be paid attention to:

- Wear protective gloves;

- Pay attention to the safety protection of the operator, and the heating plate should be placed in the special heating plate bracket after welding;

- The heating plate should be cooled before transportation to avoid fire;

- After welding, place the heating plate in a safe place to avoid accidental burns by outsiders;

- After welding, do not cut off the power supply of the heating plate;

- Do not touch the heating plate with your hands;

2. Milling cutter

- Before milling the pipe (piece), make sure that the end face of the pipe is clean and free of debris, so as not to damage the cutting blade;

- After milling the pipe (piece), wait for the milling cutter to stop rotating, and then take out the milling cutter disc for storage;

- Lift the handle when pulling out the milling cutter;

- The milling cutter can only be rotated after it is installed on the welding frame;

- Do not adjust the milling cutter micro switch randomly;

3. Rack

- Check the parts/materials to be welded to ensure that they have been accurately clamped on the frame to ensure welding quality. Operators should stay away from the welding machine properly;

- When welding, if the movable chuck is in contact with the fixed chuck, do not stop it with the main switch of the welding machine, just move the pressure adjustment lever to open the chuck. Yes;

- When transporting the shelf, please make sure that all the clips are tightened so as not to fall off.

Previous post: