07

Nov

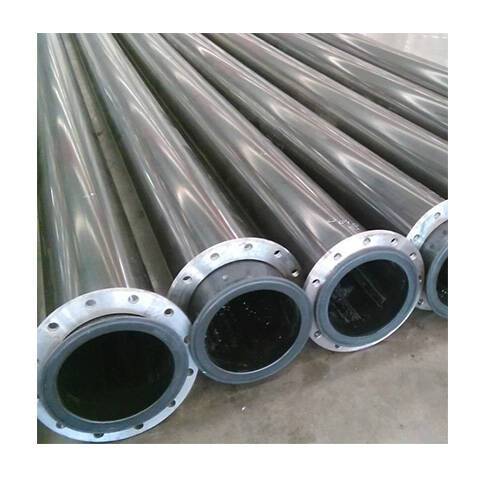

Selecting the Right Diameter For HDPE Drainage Pipes

Selecting the right diameter for your HDPE (High-Density Polyethylene) drainage pipes is crucial for a functional and efficient drainage system. This guide provides a comprehensive understanding of how to choose the correct pipe diameter, ensuring a balance between cost, performance, and longevity, which is essential for homeowners, contractors, and engineers alike.

Selecting the Right Diameter For HDPE Drainage Pipes

Understanding Flow Rate and Its Impact on Diameter

Flow rate is the first and foremost consideration when determining pipe size. To calculate the required diameter, start with the maximum expected flow rate, typically expressed in gallons per minute (gpm) or cubic feet per second (cfs). This data can stem from historical averages or from calculations based on the area being drained.

Table 1: Sample Flow Rate Calculation

| Drainage Area (sq ft) | Rainfall Intensity (in/hr) | Runoff Coefficient | Flow Rate (gpm) |

| 1,000 | 3.5 | 0.6 | 175 |

| 5,000 | 3.5 | 0.6 | 875 |

| 10,000 | 3.5 | 0.6 | 1750 |

Using the runoff coefficient for impermeable surfaces, the flow rate can be gauged to determine the necessary HDPE pipe diameter(Reference article:HDPE Pipe Specification Size Table).

Pipe Slope and Diameter: The Relationship

The slope of the pipe directly influences the velocity of water. A good rule of thumb is that a steeper slope can reduce the needed diameter since it increases water velocity, preventing sediment buildup. The correct slope ensures that pipes work effectively without being oversized, which can add unnecessary costs.

Employing Manning’s Equation for Diameter Calculation

Manning’s equation (A coefficient that reflects the impact of the roughness of the pipe wall on the water flow.) is a cornerstone in hydraulic engineering for calculating pipe size. It integrates the pipe’s slope, roughness coefficient, and the flow rate to ascertain the required diameter for efficient operation.

Manning’s Equation: [ V = \frac{1}{n}R^{2/3}S^{1/2} ] where ( V ) is the velocity, ( n ) is the Manning’s roughness coefficient, ( R ) is the hydraulic radius, and ( S ) is the slope of the energy grade line (essentially the pipe slope).

[Notes and references From Wikipedia : Manning formula and Manning coefficient]

Surge and Fatigue: Why They Matter

Surge pressure, or water hammer, is a phenomenon that can cause a spike in pressure due to abrupt changes in water flow. When selecting a pipe diameter, consider the potential for such events and choose a size that helps mitigate this risk, ensuring the longevity of your pipeline.

Load Handling and Cover Requirements

Proper installation includes accounting for the load that the HDPE pipe will bear. This includes the weight of the earth above it and any above-ground loads, like vehicles or equipment. The minimum cover is the least amount of earth or pavement required to protect the pipe, which varies depending on the diameter of the HDPE pipe.

Compliance with Standards and Codes

Regulations may dictate certain diameters or installation practices for HDPE pipes. Standards from the American Society for Testing and Materials (ASTM) and the American Association of State Highway and Transportation Officials (AASHTO) provide benchmarks for design and installation.

Anticipating Future Conditions

While current flow rate data is essential, anticipating future conditions, like community growth or climate change, can save money and effort in the long term. Designing with an eye towards the future is a smart investment.

Economic Considerations

When selecting HDPE pipe diameters, the balance between initial investment and future savings is key. Larger diameters may cost more upfront but can reduce long-term maintenance needs due to clogs or slow water velocity.

Putting It All Together: The Selection Process

To simplify the selection process, use the following steps:

- Determine the flow rate: Based on area calculations and expected rainfall.

- Assess the slope: Evaluate the area’s topography to define the available slope.

- Calculate using Manning’s: Apply Manning’s equation to find the appropriate diameter.

- Account for surges: Factor in surge events to ensure durability.

- Consider load and cover: Use industry guidelines to determine the required depth and bedding.

- Ensure compliance: Verify that your pipe choices meet all regulatory requirements.

- Plan for the future: Think ahead to avoid under-sizing your system.

Using this method, you can make a well-informed decision about the HDPE pipe diameter that will serve you best. Remember, the ideal pipe size is the one that efficiently handles the expected flow within a safe and cost-effective design framework.