14

Jan

The Lifespan of HDPE Pipes Overview

High-Density Polyethylene (HDPE) pipes are widely acclaimed for their robustness and longevity in various applications, ranging from water supply and gas distribution to sewage and industrial effluents. Understanding their lifespan is crucial for effective planning and budgeting in infrastructure projects.

Key Attributes of HDPE Pipes

- Material Strength: HDPE’s high resistance to wear and corrosion contributes to its longevity.

- Flexibility: Unlike rigid piping materials, HDPE can withstand ground movements and temperature variations.

- Chemical Resistance: HDPE is impervious to many chemicals, making it ideal for industrial applications.

Factors Affecting HDPE Pipe Lifespan

- Quality of Installation: Proper installation is critical to ensure the full lifespan of the pipes.

- Environmental Conditions: Soil composition, temperature fluctuations, and UV exposure can impact longevity.

- Pipe Specifications: Wall thickness, diameter, and quality of HDPE used can vary the lifespan.

Expected Lifespan

HDPE pipes typically offer a lifespan of 50 to 100 years, depending on the factors mentioned above. This is significantly longer than many alternative materials.

Maintenance and Inspection

Regular inspections and maintenance can extend the life of HDPE piping. This includes checking for joint integrity, surface damage, and environmental changes.

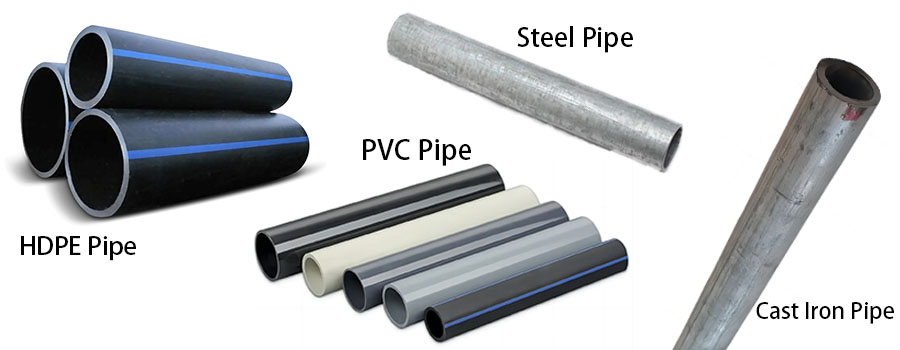

Comparison with Other Materials

In order to provide a more comprehensive comparison, it’s crucial to include additional parameters like maximum pressure tolerance and highest temperature resistance. Here’s an updated comparison table incorporating these aspects:

| Material | Expected Lifespan | Max Pressure Tolerance | Max Temperature Resistance | Key Advantages |

| HDPE | 50-100 years | Up to 1600 kPa | Up to 60°C | Flexibility, durability |

| PVC | 30-40 years | Up to 1200 kPa | Up to 65°C | Cost-effective |

| Steel | 20-30 years | Up to 5000 kPa | Up to 250°C | Strength |

| Cast Iron | 25-30 years | Up to 2100 kPa | Up to 350°C | Rigidity |

Analysis of the Data

- HDPE Pipes exhibit a remarkable balance of longevity and pressure tolerance, suitable for various environmental conditions. Their temperature resistance is adequate for most civil and industrial applications.

- PVC Pipes, while offering lower pressure tolerance, are cost-effective and have a slightly higher temperature resistance than HDPE.

- Steel Pipes stand out in terms of maximum pressure tolerance and temperature resistance, making them suitable for high-stress and high-temperature applications.

- Cast Iron Pipes offer high rigidity and temperature resistance but lag in terms of pressure tolerance and lifespan compared to HDPE.

The data used in this table is based on the latest industry standards and research. For the most current and specific data, referencing industry publications and manufacturer datasheets is recommended.

Case Studies and Industry Data

Recent studies show HDPE pipes outperforming other materials in longevity and maintenance costs. For example, a study by the Plastic Pipe Institute (PPI) demonstrates the effectiveness of HDPE in municipal water systems.

Conclusion

HDPE pipes offer an impressive balance of durability, flexibility, and cost-effectiveness, making them a preferred choice in various industries. Their extended lifespan not only ensures reliability but also contributes to environmental sustainability by reducing the frequency of pipe replacements.

For detailed data and further reading, industry-specific articles and studies provide valuable insights.