18

Dec

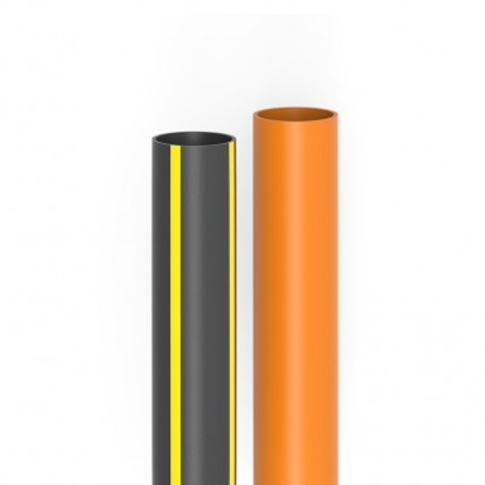

The Versatility of HDPE Pipes in Industry

HDPE pipes are renowned for their durability, flexibility, and resistance to corrosion and chemicals. Made from a thermoplastic polymer, HDPE pipes are widely used in various industrial applications due to their ability to withstand harsh environments. Their versatility is evident in sectors like municipal water supply and sewage systems, where they are used for their leak-proof and low maintenance qualities. In the chemical industry, HDPE pipes are favored for transporting corrosive substances due to their chemical resistance. The agriculture sector employs these pipes for efficient irrigation systems, benefiting from their flexibility and ease of installation. Additionally, HDPE pipes play a crucial role in the mining industry for slurry transport and in the oil and gas sector for safe and reliable pipeline solutions. Their environmental sustainability, as recyclable materials, further adds to their appeal across industries.

Characteristics of HDPE pipes

Composition and Physical Properties of HDPE Pipes

High-Density Polyethylene (HDPE) pipes are made from a thermoplastic polymer derived from petroleum. The material composition includes approximately 95-98% polyethylene, a type of plastic, and 2-5% additives that enhance properties such as UV resistance and flexibility. The key physical properties of HDPE pipes include:

- High Density: Provides strength and rigidity, making the pipes durable.

- Corrosion Resistance: Naturally resistant to corrosion and chemical attacks.

- Flexibility: Allows for bending without breaking, suitable for various terrains.

- Low Temperature Resistance: Remains pliable and functional in cold temperatures.

- High Impact Resistance: Can withstand significant impacts and pressures.

- Lightweight: Easier to transport and handle compared to traditional pipe materials.

Production Process of HDPE Pipes

The manufacturing of HDPE pipes involves several steps:

1. Raw Material Preparation: Polyethylene resin is prepared and mixed with necessary additives.

2. Extrusion: The resin mixture is fed into an extruder, where it is heated and melted. This molten plastic is then forced through a shaped die to form the pipe.

3. Cooling and Solidification: The extruded pipe is cooled in a water bath or by air, solidifying into its final shape.

4. Cutting and Finishing: The continuous pipe is cut into desired lengths and inspected for quality and compliance with standards.

5. Quality Testing: Pipes undergo various tests, including pressure testing and checking for imperfections.

Application of HDPE Pipes in Industry

> Municipal Engineering: for Water Supply and Sewage Systems. In this sector, HDPE pipes are widely used for their leak-proof joints, corrosion resistance, and long service life. They are ideal for transporting drinking water and handling sewage due to their non-toxic nature and resistance to environmental stress cracking.

> Chemical Industry: HDPE pipes are highly valued in the chemical industry for transporting aggressive chemicals. Their chemical inertness makes them resistant to a wide range of corrosive substances, ensuring safe and long-lasting conduits for chemical transport.

> Agriculture for Irrigation Systems: In agriculture, HDPE pipes are used in irrigation systems because of their flexibility, durability, and ease of installation. They can efficiently distribute water over large areas, withstand various environmental conditions, and are suitable for surface and subsurface irrigation systems.

> Mining for Slurry and Tailings Management: The mining industry employs HDPE pipes for transporting abrasive slurries and managing tailings. Their high impact and abrasion resistance make them suitable for handling the rough and abrasive materials commonly found in mining operations.

> Oil and Gas Industry for Gathering Lines: In the oil and gas sector, HDPE pipes are used for gathering lines due to their high strength, flexibility, and chemical resistance. They are effective in safely transporting oil, gas, and other by-products, and their durability ensures long-term reliability in challenging environments.

Advantage of HDPE Pipe in Industry

- Corrosion Resistance: Their inherent resistance to corrosion and rust is a major advantage in industrial settings. This property extends the life of the pipes, especially in environments where exposure to corrosive substances is common.

- High Flexibility and Toughness: HDPE pipes are highly flexible and tough, allowing them to withstand environmental stresses like soil movement and seismic activities. This flexibility also enables them to be used in varied terrains and conditions without breaking.

- Leak-Free Joint Design: The ability to create seamless and leak-free joints through heat fusion is a critical advantage. This ensures the integrity of fluid transport, particularly vital in industries where leakage could lead to significant operational disruptions or environmental hazards.

- Chemical Stability: HDPE’s chemical inertness makes these pipes ideal for transporting a wide range of chemicals without degradation or reaction. This stability is crucial in sectors like chemical manufacturing, where pipe integrity is essential for safety and efficiency.

- Ease of Installation and Maintenance: The lightweight nature of HDPE pipes simplifies installation, reducing labor and machinery costs. Their durability and resistance to various stresses also mean less frequent maintenance, making them a cost-effective solution over time.

- Environmental Performance: HDPE pipes contribute positively to environmental sustainability. They are recyclable, reducing waste in the long term. Furthermore, their production and transportation processes have a lower carbon footprint compared to traditional piping materials, aligning with eco-friendly industrial practices.

In summary, the use of HDPE pipes in industrial applications brings significant benefits, including durability, cost savings, and environmental sustainability, making them a superior choice in various industrial scenarios.